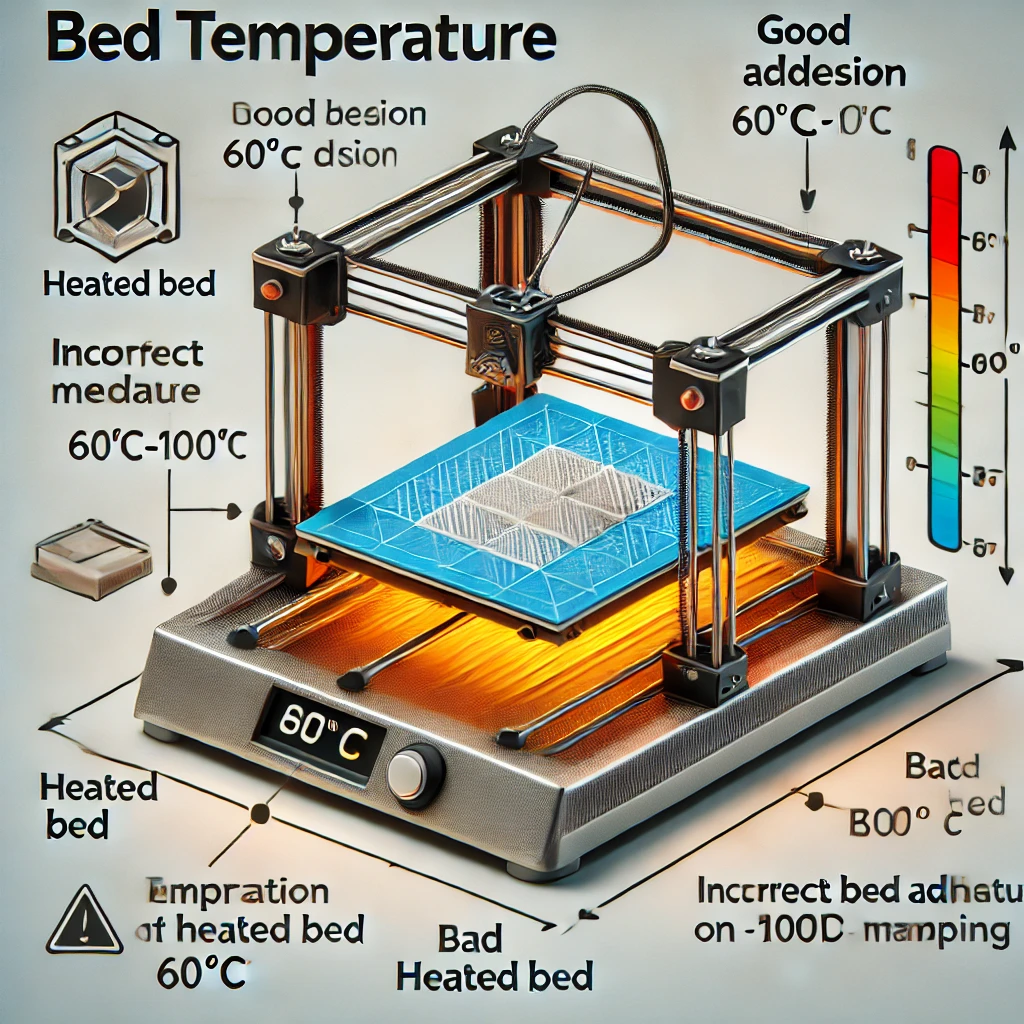

Bed Temperature refers to the temperature of the heated bed on a 3D printer. It is the temperature of the printer’s build platform during the printing process. The heated bed helps improve print quality by ensuring better adhesion of the material to the print surface and minimizing issues during printing.

Why is Bed Temperature Important?

- Prevents Warping:

- Uneven cooling of the material during printing can cause warping, especially with thermoplastics like ABS or PETG. Proper bed temperature slows down the cooling process and reduces warping.

- Improves Adhesion:

- The heated bed provides better adhesion for the first layer, ensuring that the print stays stable on the platform throughout the process.

- Reduces Cracking:

- For some materials, the heated bed prevents the model from cracking or splitting due to shrinkage during the printing process.

Recommended Bed Temperature for Different Materials

Each material requires a specific bed temperature for optimal results. Below are the recommended ranges for some common 3D printing materials:

| Material | Recommended Bed Temperature (°C) | Notes |

|---|---|---|

| PLA | 50-70°C | PLA has low bed temperature requirements, but heating improves adhesion. |

| PETG | 70-90°C | A higher temperature helps prevent warping and cracking. |

| ABS | 90-110°C | A high bed temperature slows cooling, preventing warping and layer separation. |

| TPU | 40-60°C | TPU is flexible and does not require high bed temperatures. |

| Nylon | 90-110°C | Nylon is prone to warping and benefits from a high bed temperature and enclosed printing. |

| PC (Polycarbonate) | 100-110°C | High bed temperature ensures adhesion and reduces shrinkage and warping. |

How to Set the Bed Temperature

- Using Slicer Software:

- In slicer software (e.g., Cura, PrusaSlicer), you can set the recommended bed temperature for each material. For example, use 50-60°C for PLA and 100-110°C for ABS.

- Test Prints:

- Print a temperature tower to find the optimal bed temperature for your filament and print settings.

- Adjust Based on Bed Surface:

- If you’re using different bed surfaces (e.g., glass, magnetic sheets, PEI plates), adjust the bed temperature slightly to suit the material’s adhesion requirements.

Important Considerations

- Too High Bed Temperature:

- This can cause the first layer to over-soften and make it difficult to remove the print after completion.

- Ensure Even Heating:

- Make sure the bed heats evenly to avoid warping or inconsistent adhesion across the model’s base.

- Cooling Fan Settings:

- For materials like ABS, turning off the cooling fan can prevent rapid cooling and reduce warping of the first few layers.